- Plastic Pallet Molding Machine,Compressed Plastic Machine -

Plastic Pallet Molding Machine,Compressed Plastic Machine

Introduction of plastic pallet compression machine

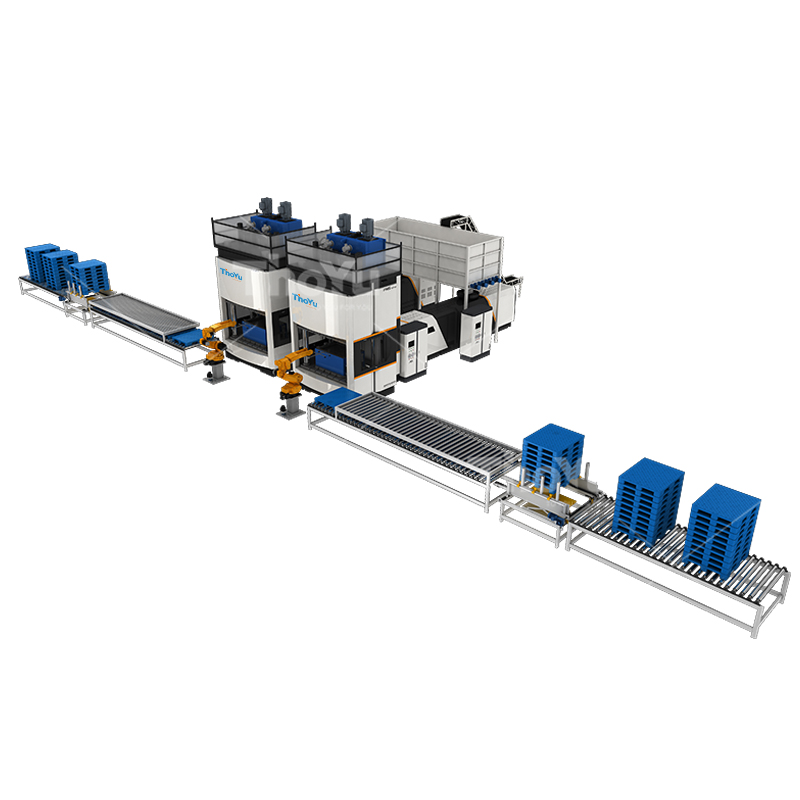

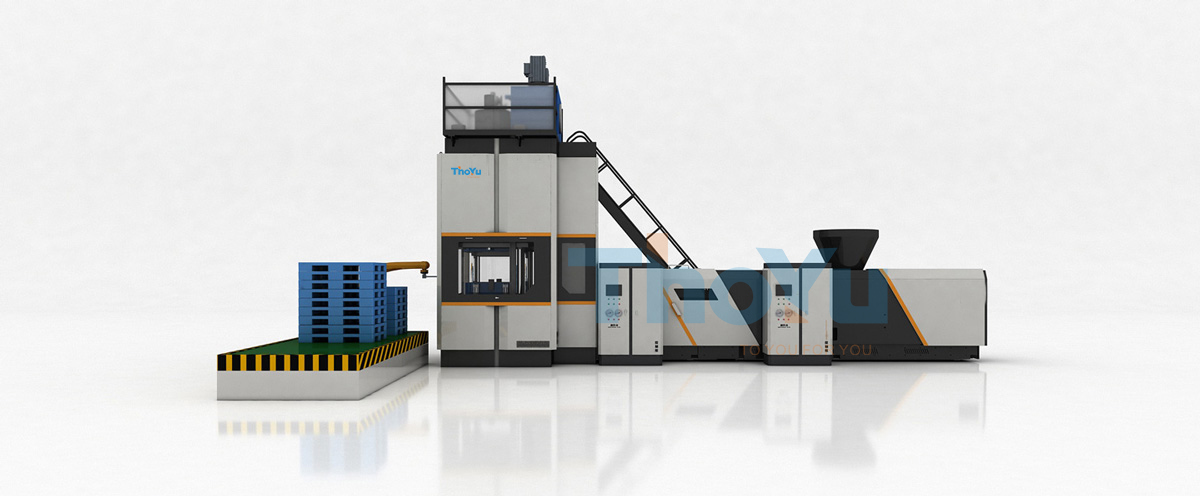

The whole machine of plastic pallet press consists of hydraulic system, electrical system, mold part and structural frame part. The hydraulic system provides enough hydraulic power for the plastic pallet press to produce plastic pallets, and the electrical system controls the operation of the entire machine. The mold is the core part of the pallet compression molding machine. The molten plastic is cooled and held in the mold, and finally formed into a molded plastic pallet. The formed plastic pallets can be taken out and palletized by a robotic arm for automated production.

The working principle of plastic pallet press machine

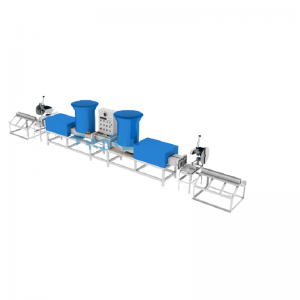

Usually recycled waste plastic needs to be washed and shredded before drying. The processed waste plastic can be input into the hopper of the plastic extruder through the conveyor, and the plastic extruded by the plastic extruder enters the mold above the machine. Plastic machine, the formed plastic machine can be taken out by a mechanical arm.

Technical parameters of plastic pallet press machine

| model | PM-1000 |

| pressure | 0-1000 tons (adjustable) |

| Number of hydraulic cylinders | 2 |

| molding cycle | 120 seconds |

| output | 720 tablets/24 hours |

| power | 43.6kW |

| Weight | 30 tons |

Raw material for plastic pallet machine

The raw materials of the plastic pallet machine can be PS, PP, LDPE, PVC, HDPE, PET and other plastics, or most waste plastics and composite materials. Most of the waste plastics encountered in life can be recycled and reused. In the production and processing process, the raw material cost is lower than the raw material cost of traditional plastic pallets, and the processing cost is also 50% lower than that of traditional plastic pallets. In addition, the production process of molded plastic pallets has very low requirements on raw materials, and various waste plastics and composite materials can be recycled and reused by plastic molding machines, which can greatly reduce the cost of producing plastic pallets.

The raw material cost and processing cost of injection molding pallet machine are high, resulting in the production of plastic pallets that are more expensive. In response to the above problems, our company has produced a pallet molding machine that uses recycled waste plastics to produce plastic pallets based on years of experience. The machine adopts waste plastic recycling process and compression molding process, which can effectively recycle waste plastics, Compression moulding is used to produce pallets that are inexpensive and durable. The plastic pallet compression molding machine uses various waste plastics to produce pallets. The cost of raw materials is very low. At the same time, it can customize various models and production capacity machines according to your product needs. It is an environmentally friendly waste plastic processing that conforms to the current market trend. equipment.

Advantages of plastic pallet moulding machine

1. Fully automatic production can be realized in the production and processing process, and the equipment can be operated under long-term, stable and efficient automatic control. Our redesigned machine makes the pallet manufacturing process more stable.

2. The plastic pallet press has a wide range of applications. it can not only produce plastic pallets, but also produce a variety of plastic products, such as plastic pallets, plastic boards, plastic turnover boxes, and plastic trash cans. , plastic shelves, plastic manhole covers, etc.

3.The production process is energy-saving and environmentally friendly, no waste water and waste gas will be generated during production, and the degree of pollution to the environment can be effectively reduced.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur